Quality isn’t just a department here; it’s the job. Every part, every time.

Managing Director

Certified, Structured, and Audit-Ready

Kristek is certified to AS9100 and ISO 9001, with a Quality Management System built for consistency, compliance, and continuous improvement. We welcome audits from customers and certifying bodies — using them to strengthen our systems, not just tick boxes.

Our QMS includes:

Integrated with Production Control

Our MRP system ties quality directly into the production process. It manages:

- Quotes, works orders, and job routing

- Material stock and batch-level traceability

- Shop floor data collection and scheduling

This ensures traceability, control, and real-time visibility from order to delivery — helping us stay production-focused and audit-ready.

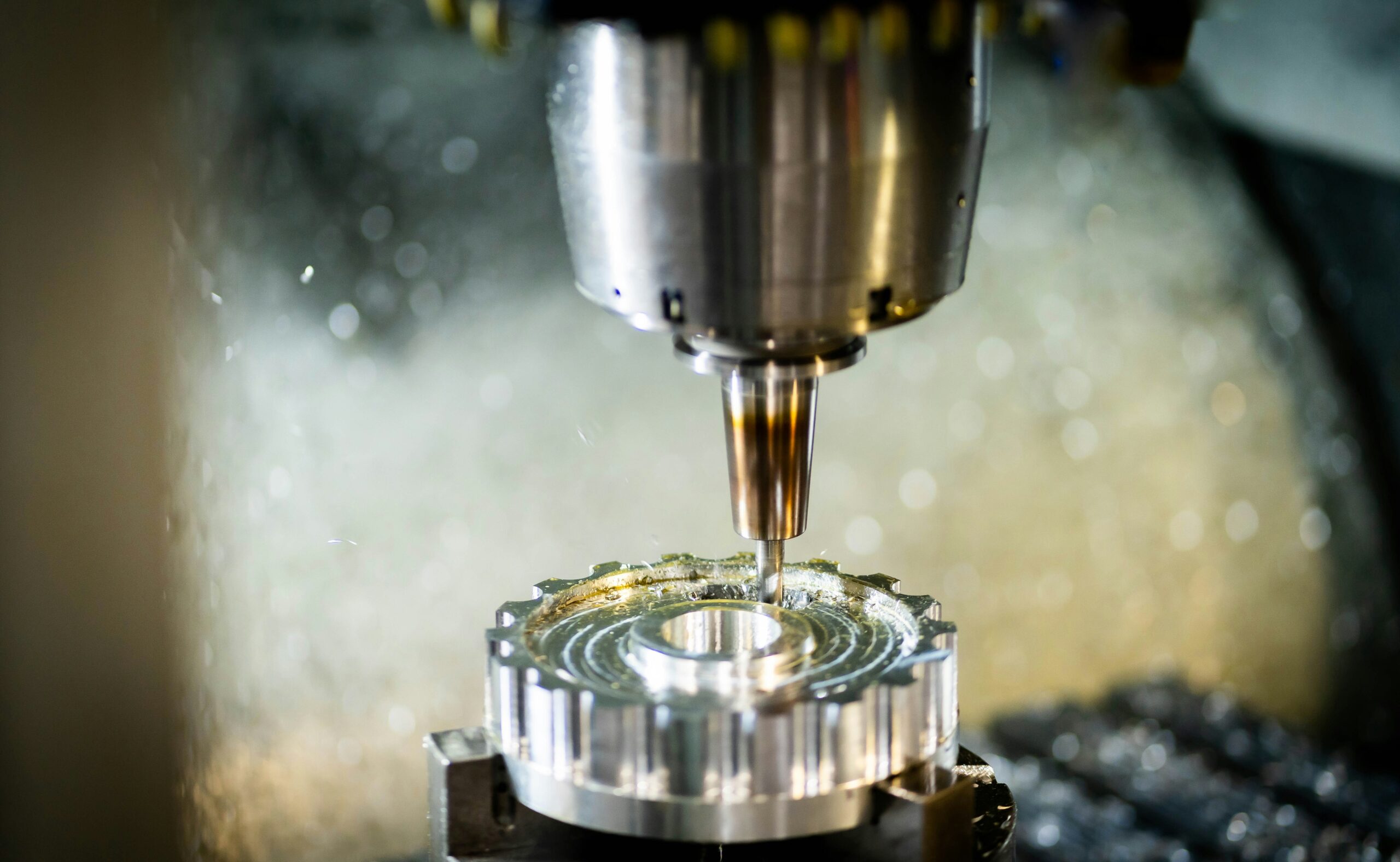

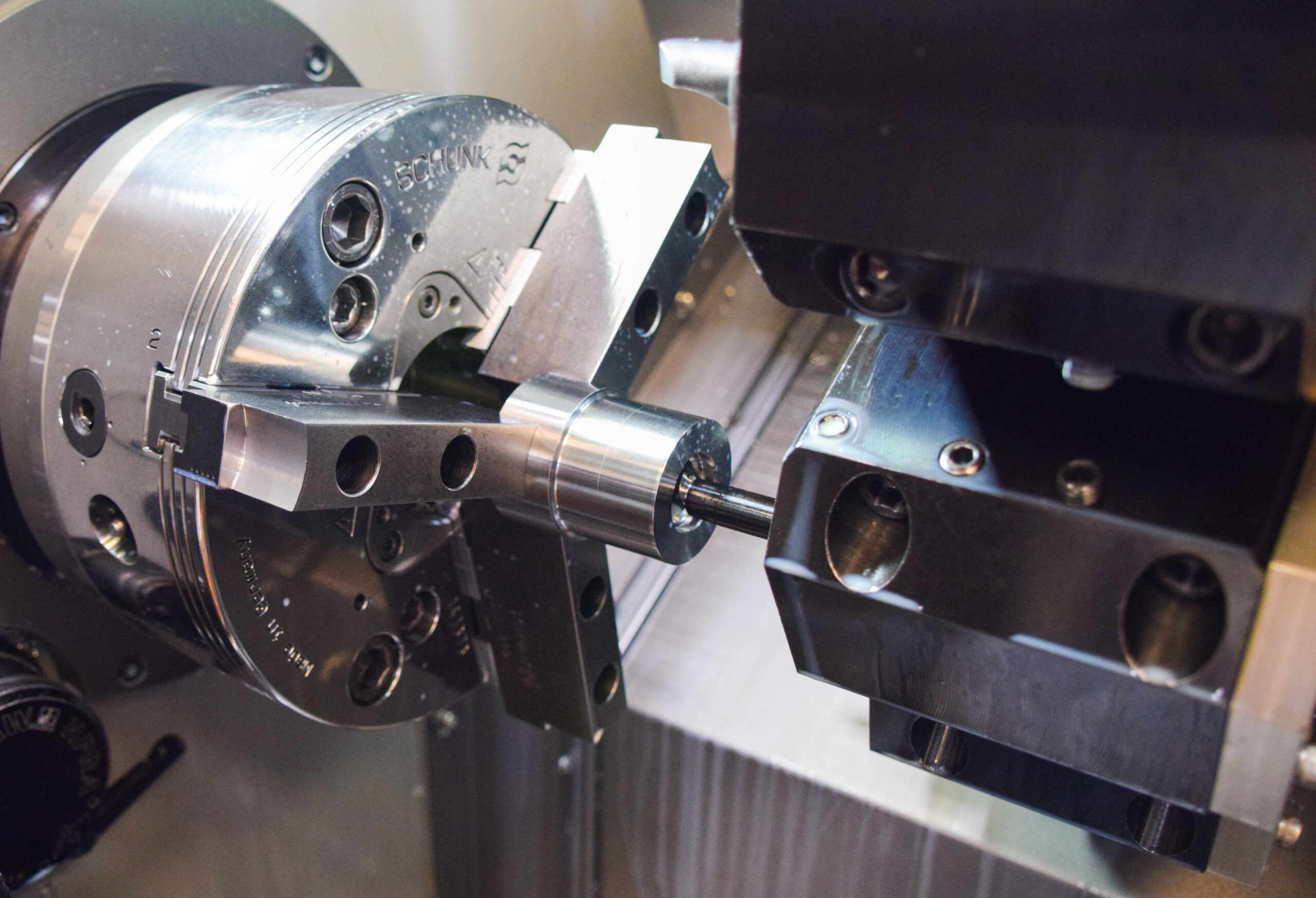

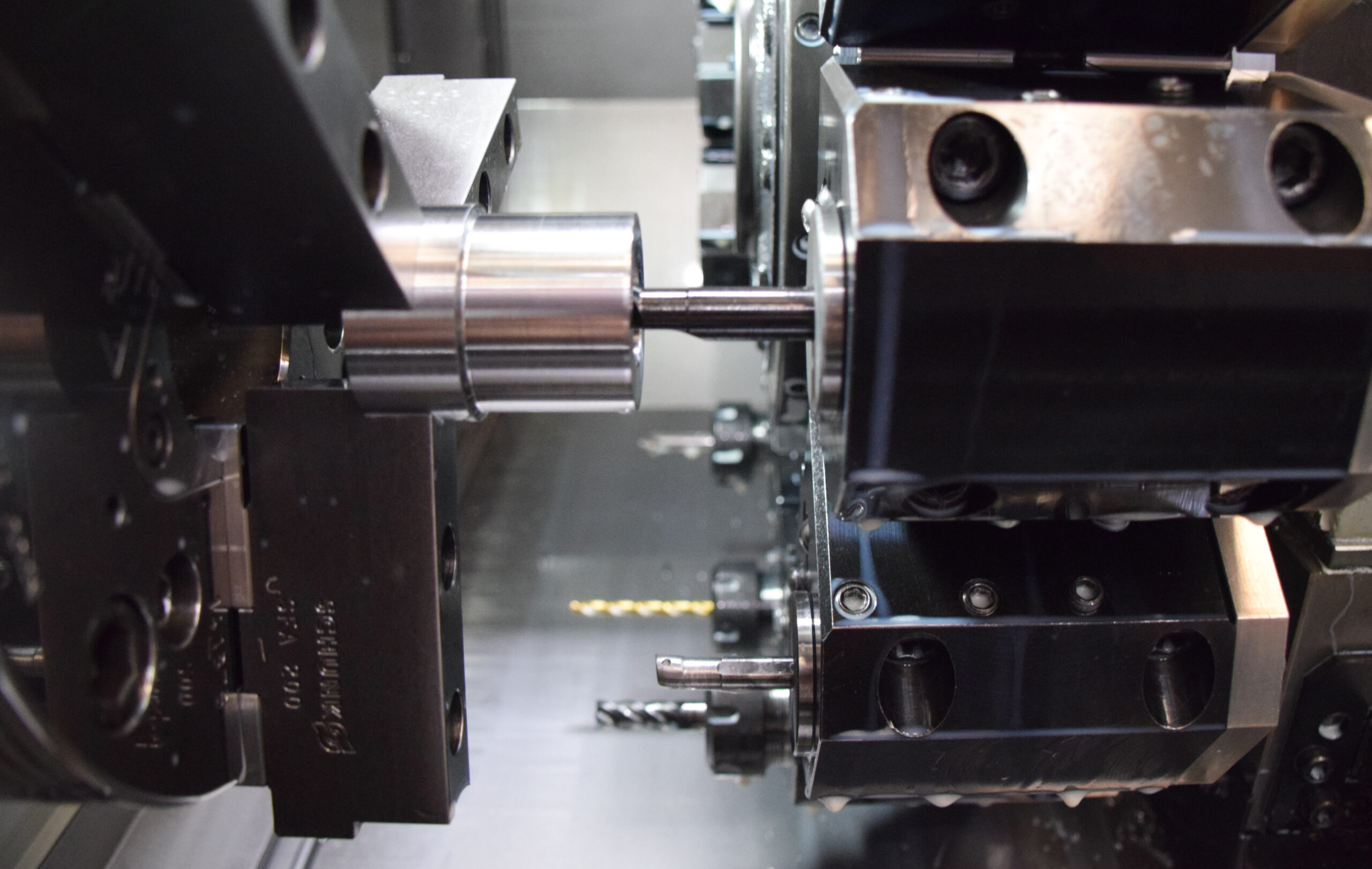

Quality-Driven Process Control

Every job follows a structured inspection process:

- First-Offs are verified by the Quality Department using a documented quality plan

- In-process checks are carried out by operators and signed off

- Final inspections confirm all specifications, finish, and documentation prior to release

Non-conforming parts are tagged, quarantined, and reviewed with full root cause and corrective action — involving staff at all levels.

We support AS9102 FAIRs and adapt our documentation to customer needs where required.

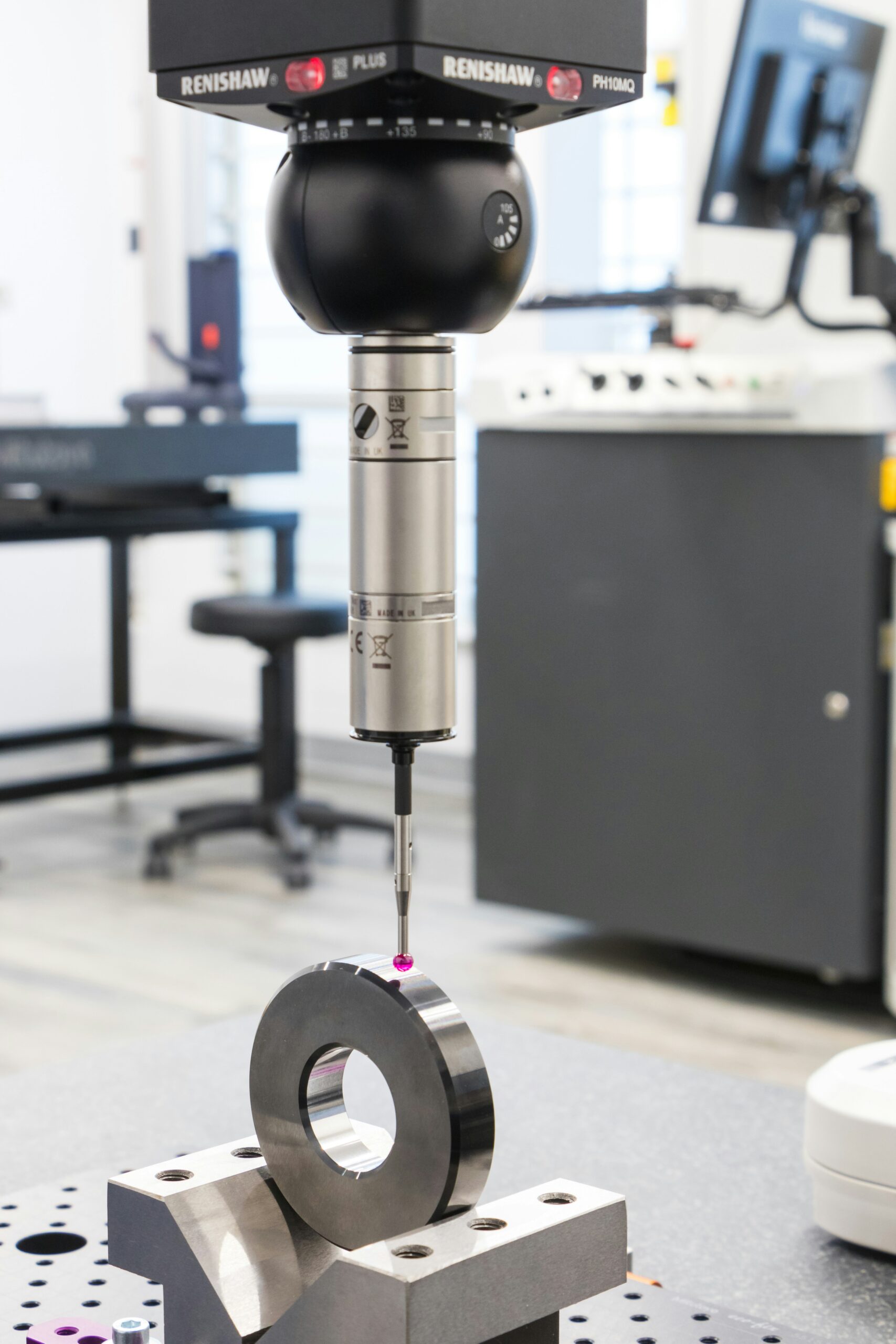

Measured, Recorded, and Retained

We measure what matters:

- In Full, On Time, In Specification (IFOTIS)

- Leading indicators to prevent downstream issues

Performance is reviewed weekly to support continuous improvement and accountability.

All quality records are scanned and securely stored digitally for 10+ years, or longer if contractually required — ensuring full traceability long after delivery.

QMS related FAQ’s

Yes – by default all orders receive a C of C, included. However, we can also provide full First Article Inspection (FAI) reports and dimensional inspection reports, if required. All inspections are carried out in-house using calibrated CMM and precision tools. For FAI we use the AS9102 standard but can use customer specific reports too.

Yes – nearly all the equipment is calibrated externally (either sent away, or calibrated onsite). This is to ensure that the gauges and equipment we are using to verify your machined parts, are safe to use.

All inspection equipment have unique serial numbers, and are fully traceable from cradle to grave.

Yes. Kristek Precision is fully AS9100 Certified, which means our quality management system meets the aerospace and defence industry’s standards. We follow rigorous inspection and documentation protocols on every job.

You can view our certification here.

Yes – every order is contract reviewed. This process is used to identified changes, or high-risk activities (e.g. short delivery date).

Actions from the Contract Review are assigned to an owner, to make sure the action is completed, de-risking the contracts and increasing communication and visibility of the risks.